From the late 1950s the LEGO Group establishes mold manufacturing plants outside Billund, because the need for specialized molds demands staff, which can be difficult to attract to Billund.

The first mold manufacturing plant outside Billund is set up in 1958 in Germany followed by a plant in the Danish town Vejle, in 1959 and in 1974, the LEGO Group sets up its first mold production department in Switzerland.

LEGO Werkzeugbau in Hohenwestedt, Germany

Mold production in Hohenwestedt commences in 1958 in the basement of the LEGO Group’s German sales company, LEGO GmbH – made necessary by the company’s vigorous growth in the second half of the 1950s. In 1962, the mold-manufacturing workshop moves into its own premises in Hohenwestedt, becoming a separate company in 1964 under the name LEGO Werkzeugbau GmbH.

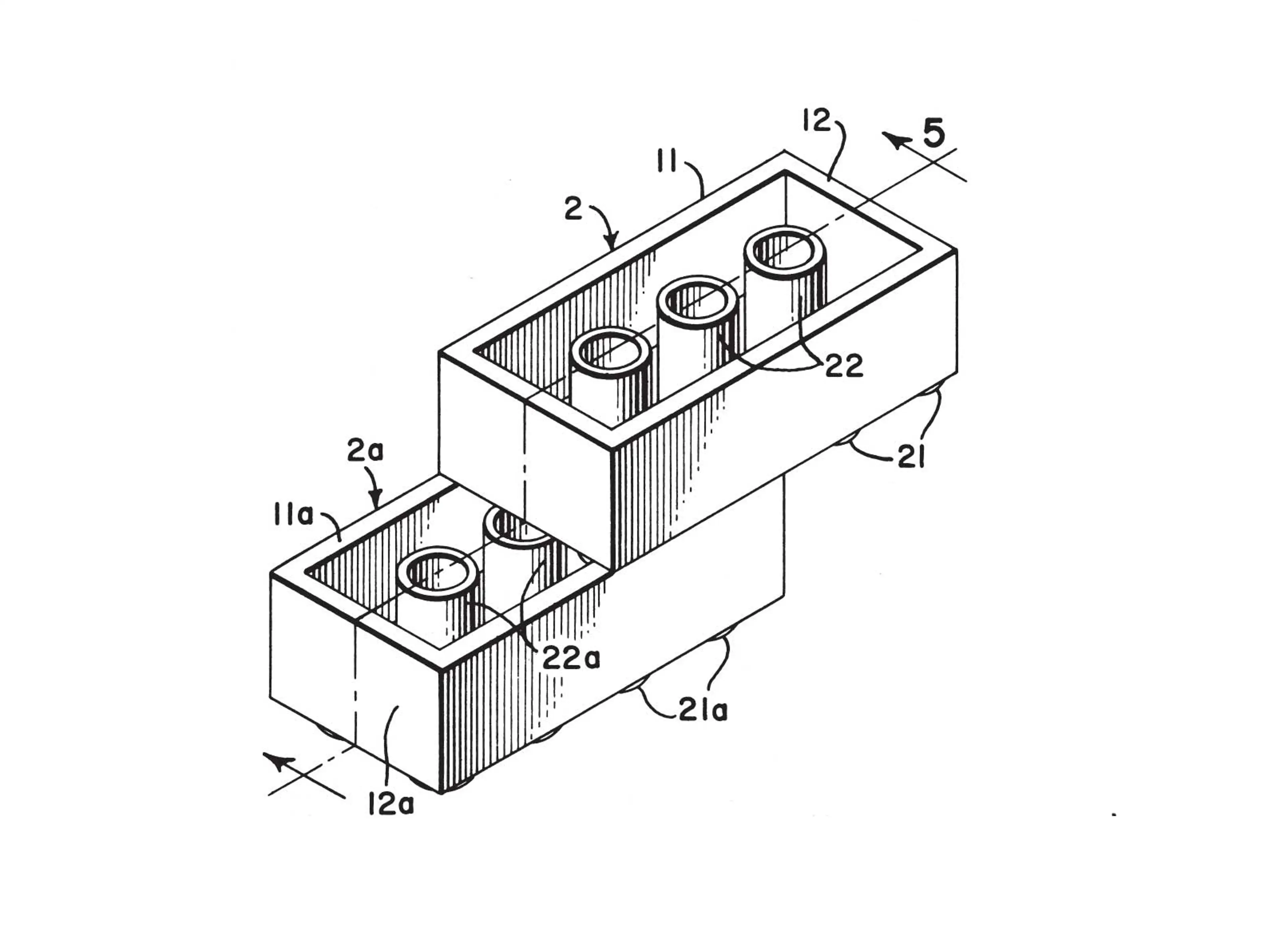

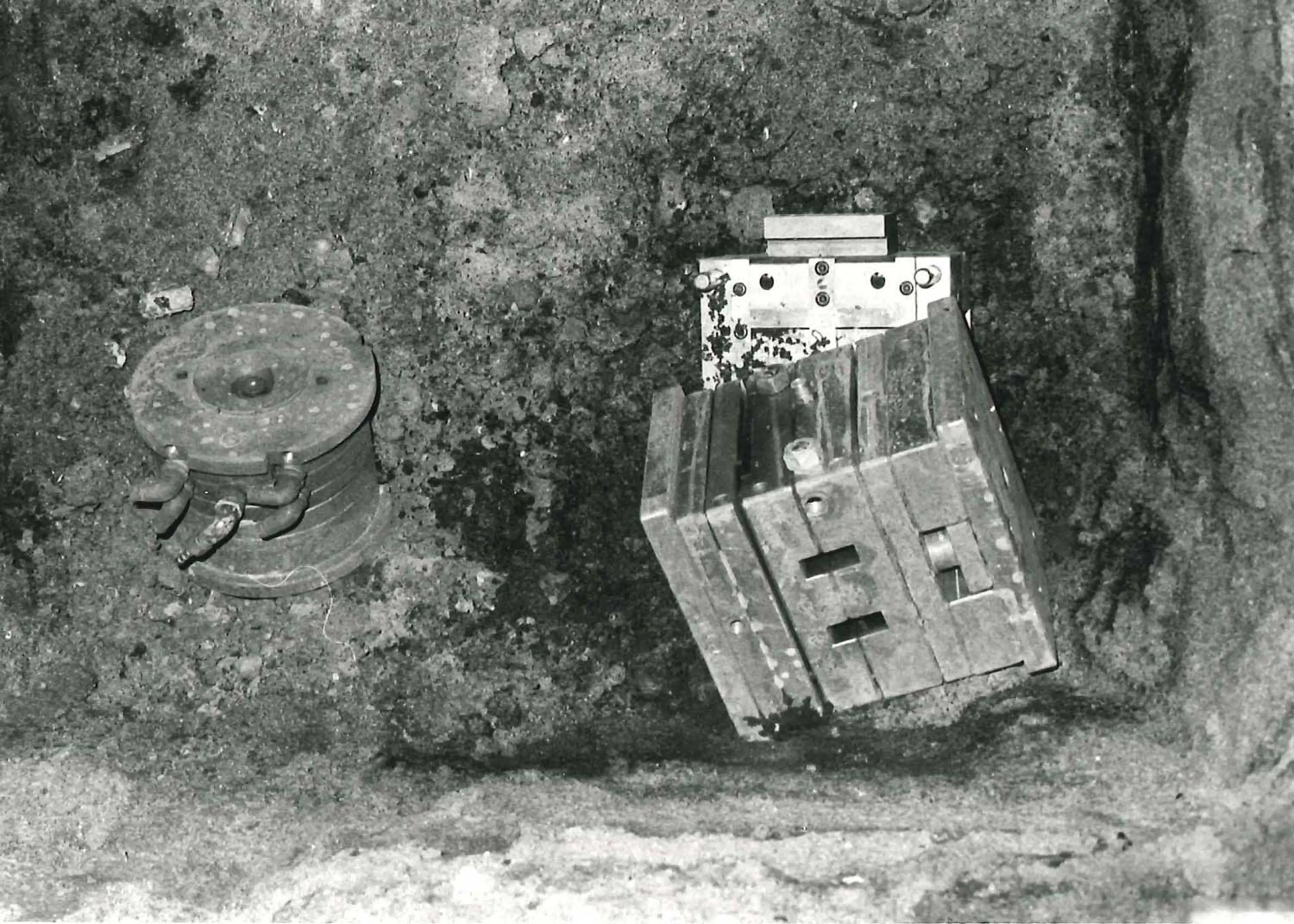

The first molds manufactured in Hohenwestedt are for molding LEGO® plastic cars on a scale of 1:80

LEGO Werkzeugbau GmbH in Hohenwestedt mainly manufactures molds for established elements, but also occasionally new‑product molds. In 1972, the toolmaking capacity is 130 molds a year, employing 35 toolmakers. By 1980, the unit has an annual output of approx. 150 molds.

The recycling principle is important: most of the molds are built into a “box” unit, which can be reused when the actual mold is worn and needs to be replaced.

In 2002, the Hohenwestedt Prototype and Mold Manufacturing is sold to a Canadian company called Wentworth Technologies Inc. Corp.

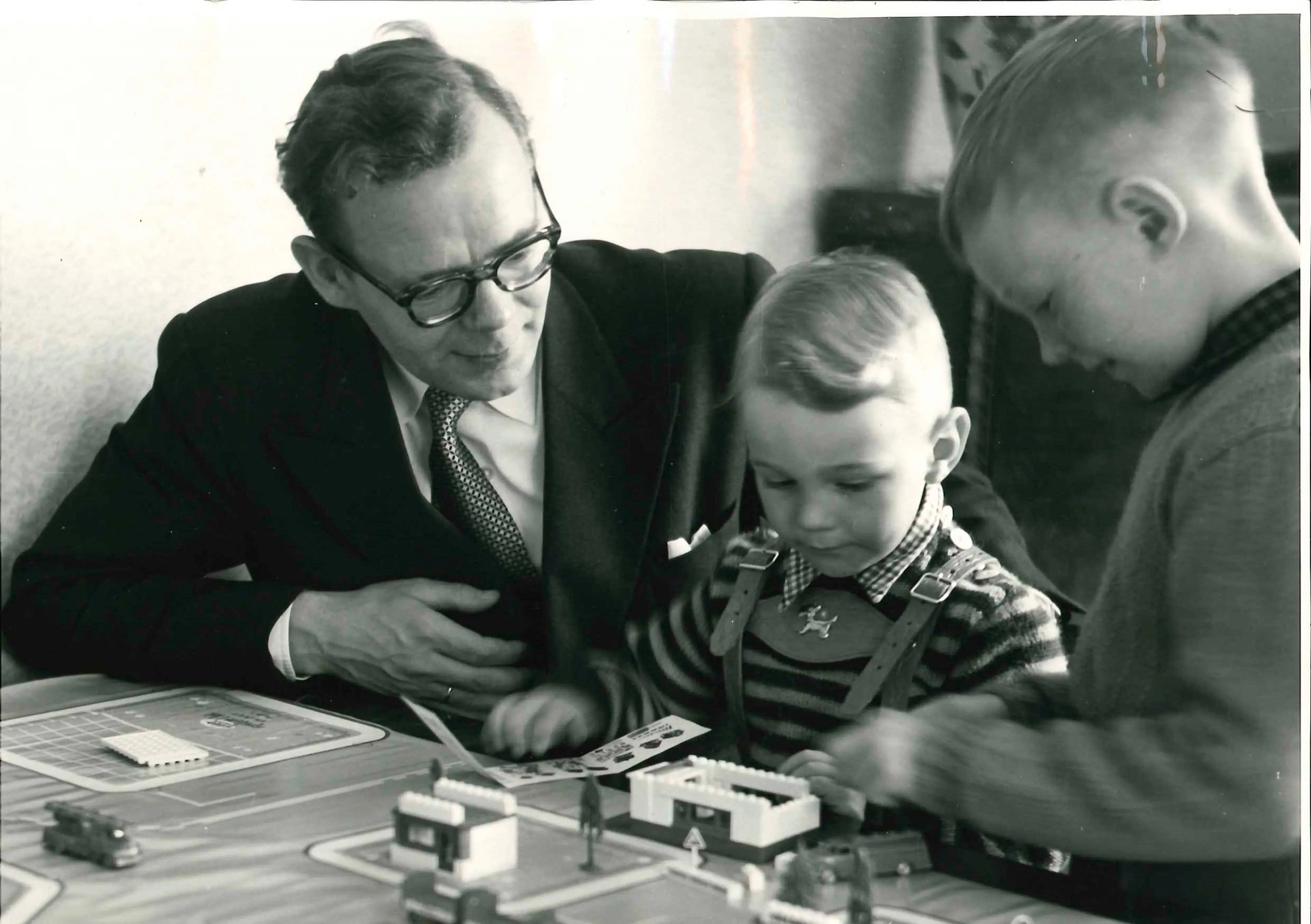

LEGO Werkzeugbau in Hohenwestedt, 1980s

LEGO Form in Vejle, Denmark

A toolmaking unit, LEGO Form, is set up in the nearby town of Vejle in 1959. Ove Nielsen, manager of the Mold Manufacturing Workshop in Billund, transfers to Vejle, where he is manager until 1976.

In 1972, manufacturing capacity is 80 molds a year, employing 30 toolmakers. It takes between 300 and 1500 hours to produce a molding form. One molding form weighs between 30 and 300 kilos – the average weight being 174 kilo.

LEGO Form exists from 1959 to 1977, when the manufacturing workshop shuts down on account of overcapacity.

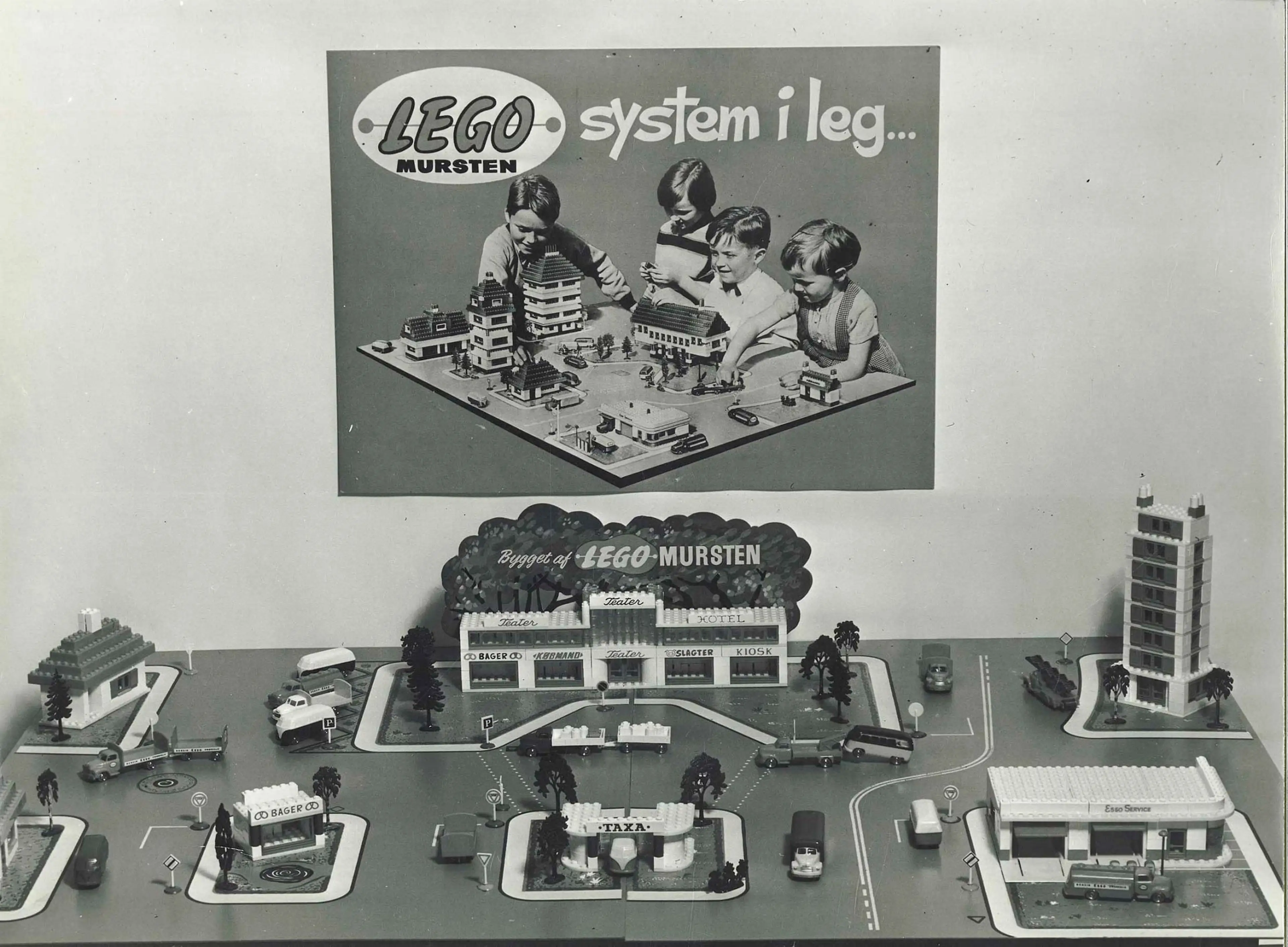

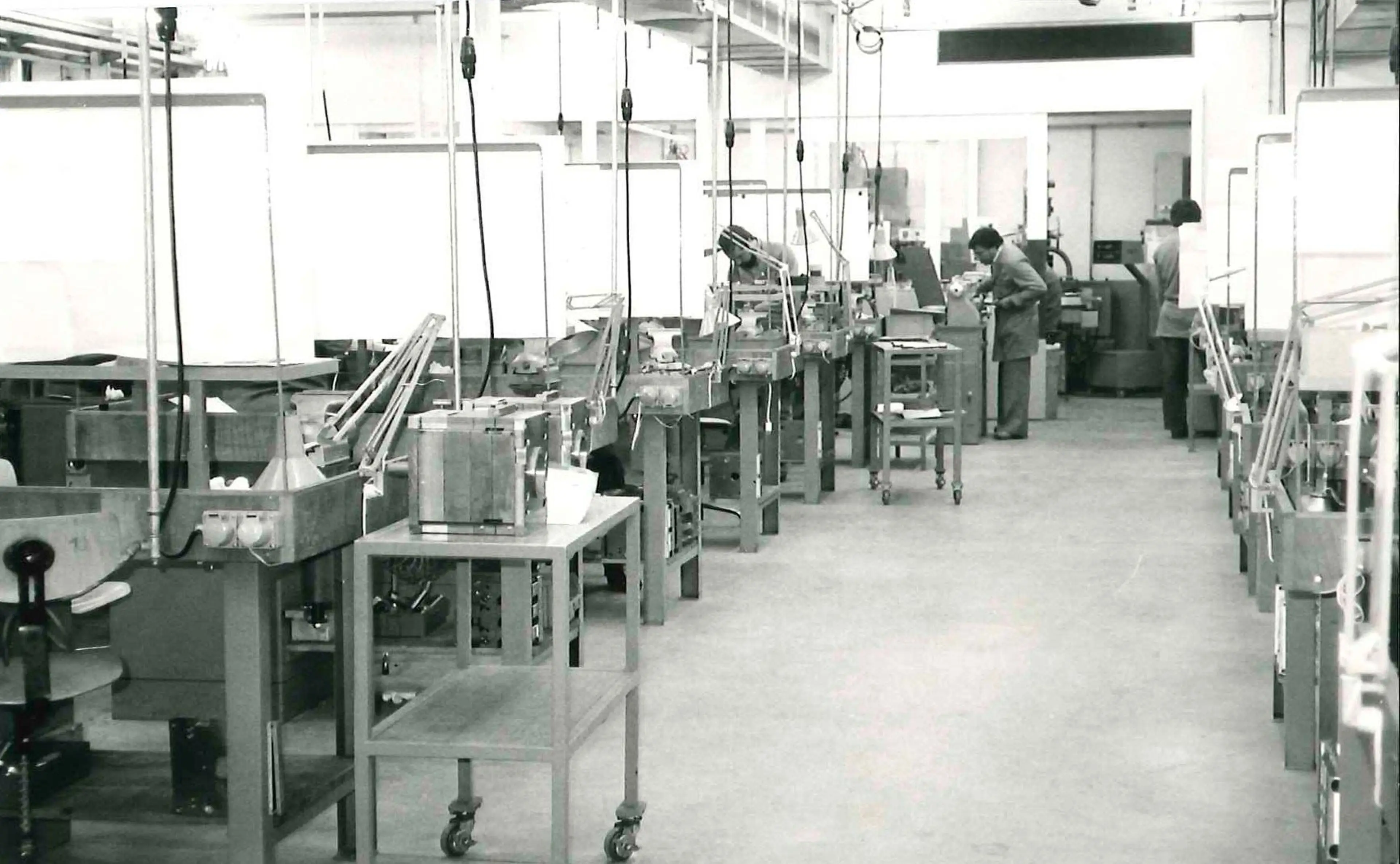

LEGO Form in Vejle, 1961

Mould manufacturing in Switzerland

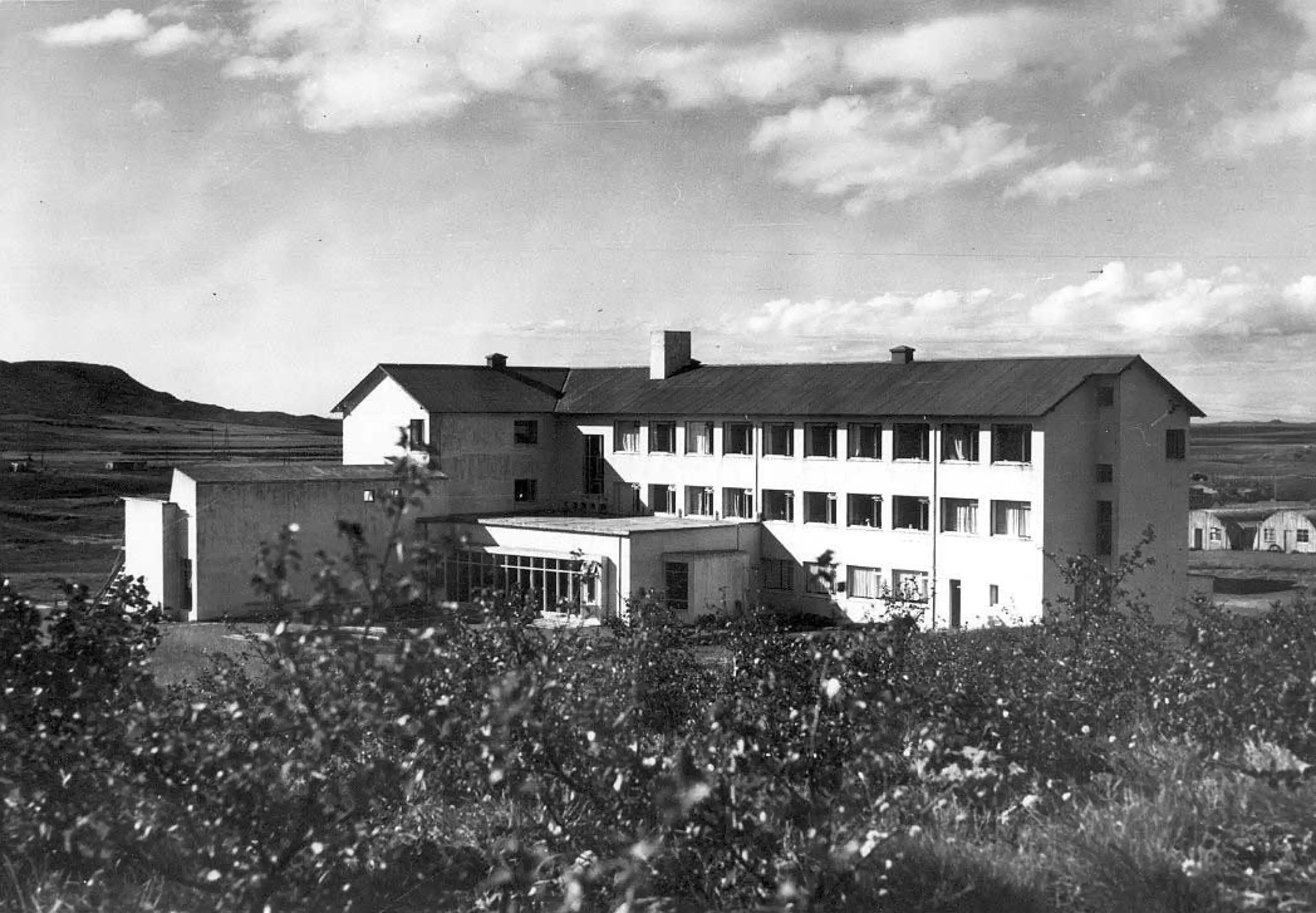

Hans Schiess, technical director in Billund, who was headhunted to the company in 1961 due to his profound knowledge of molding and molding processes, wants to return to his native Switzerland. In addition, Switzerland can offer a supply of available, qualified toolmakers and a favourable business climate. For these reasons a mold manufacturing facility is set up in Switzerland in 1974. In the years to come the LEGO presence is expanded as more factories are set up.

LEGO Werkzeugbau in Baar

The LEGO Group sets up a test molding department with process and toolmaking facilities in Baar, Switzerland in 1974. The new facility specializes in new‑product molds, including the FABULAND range. By 1980 it is manufacturing approx. 140 molds a year.

The prototype and mold manufacturing facilities continues in Baar until 1990, when it transfers to Steinhausen because of a lack of space. The molding facilities, which was added shortly after the original toolmaking facility opened in 1974, continues to be located in Baar and absorbs the vacant space left behind by the mold manufacturing workshop.

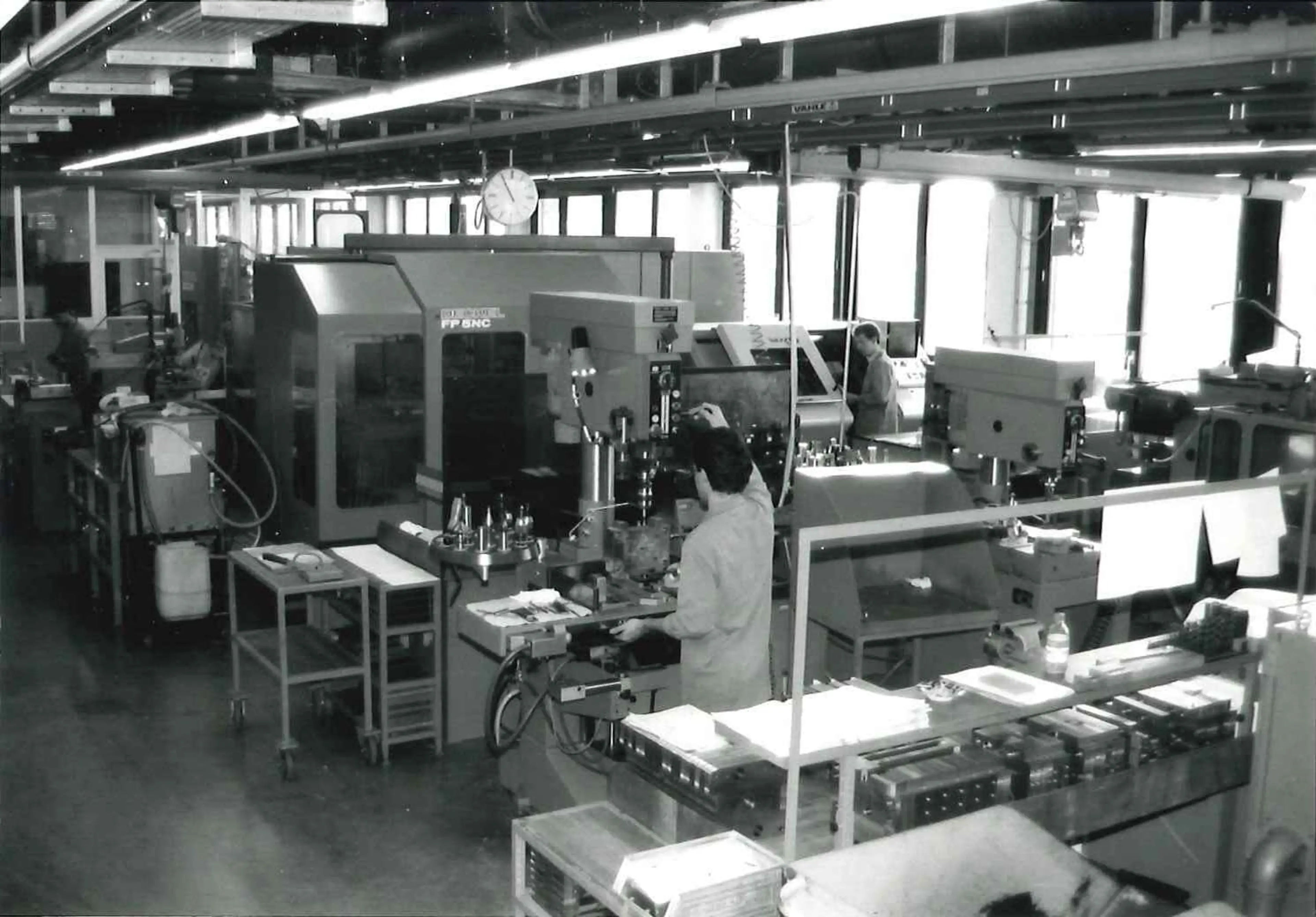

Inside the mold production facilities in Baar, 1981

LEGO Werkzeugbau in Au

In the early 1980s it becomes evident that it is not enough with three mold manufacturing workshops – in Billund, Hohenwestedt and Baar. Consequently, a fourth facility is set up in a new toolmaking plant in the Swiss town of Au. The plant opens in 1985.

In 1997 the two existing mold manufacturing workshops in Switzerland – at Au and Steinhausen (see below) – are amalgamated into one legal entity under the name LEGO Werkzeugbau AG.

The Au facility, 1990

LEGO Werkzeugbau in Steinhausen

The mold manufacturing plant in Baar has been expanded four times since it was set up, and throughout the 1980s it becomes clear that even more space is needed – but none is available in Baar. The decision is therefore made to build a new 5,000‑m² mold manufacturing facility in the town of Steinhausen, 3 km from Baar. It opens in November 1990.

LEGO Werkzeugbau AG in Steinhausen is sold in 2005 to a consortium, Wisi’on Tool AG. The tool and mold manufacturing facility is sold because it can no longer compete in terms of technology and price with modern mold production in Eastern Europe and China. At the same time the need for fewer new LEGO elements and the shorter development lead time for new products mean that capacity at Steinhausen cannot be fully utilised – with activities fluctuating between being extremely busy and very quiet. By buying in molds from external suppliers, the LEGO Group will therefore be able to reduce costs and increase flexibility.

Wisi’on Tool continues to manufacture molds, and in 2006 becomes a supplier of tools and molds to the LEGO Group. All employees transfer to Wisi’on Tool; none is made redundant.

Inside the Steinhausen facility

External partners

The LEGO Group collaborates with four external companies which supply molds to LEGO Group molding factories. Besides the mold manufacturing facility, Prototype and mold Manufacturing in Billund, that makes prototype molds and designs molds for new LEGO elements, the LEGO Group gets molding forms from the before mentioned Wisi’on Tool in Switzerland, Univac in Singapore, Nypro Tools in China and Vidan in Vietnam.