In the early 1950s the LEGO Group is buying molding tools in Copenhagen but gradually, as quality standards in production rise and become more clearly defined, the need arises for the company to have its own tooling department.

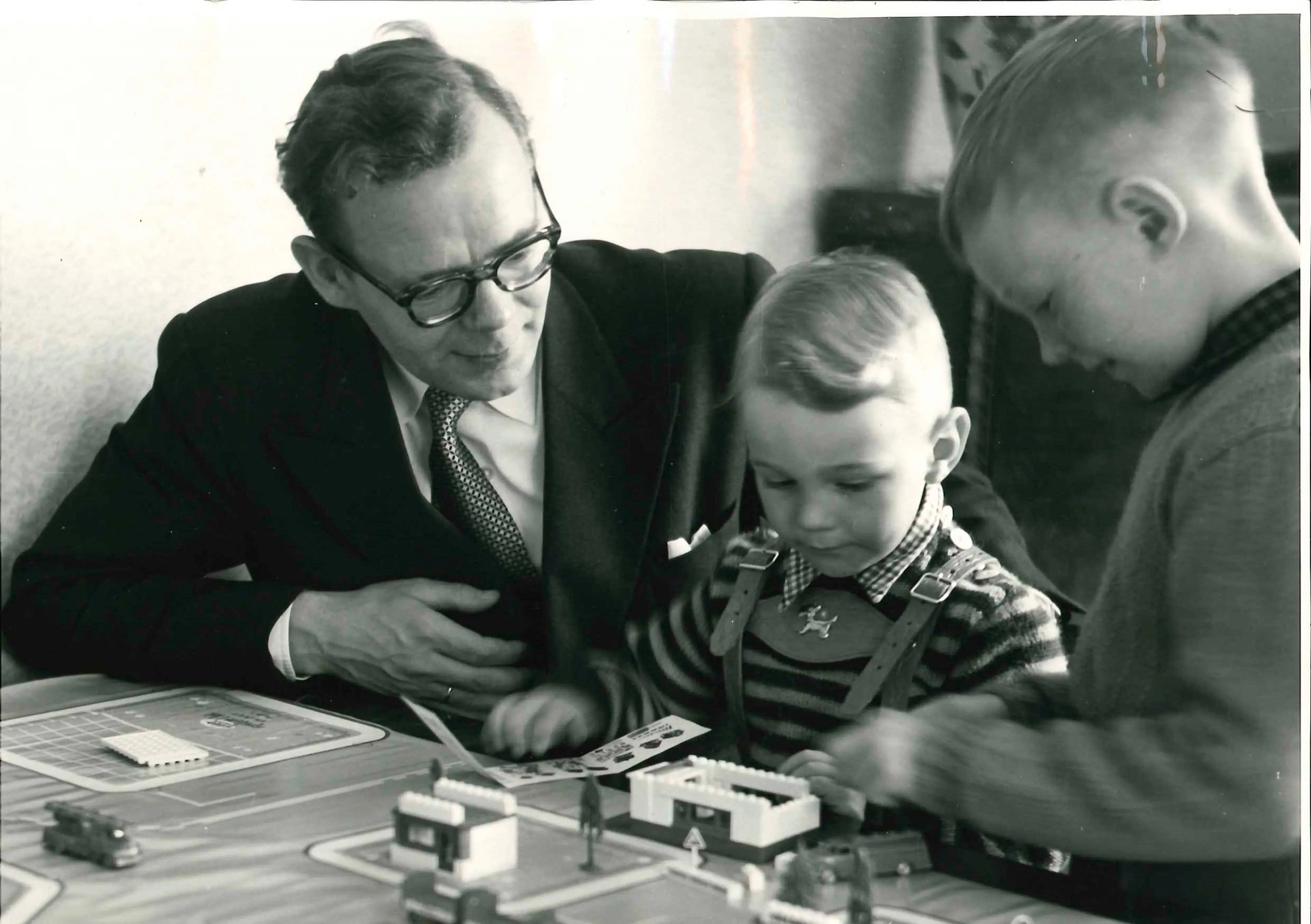

Mold production begins in Billund in 1953, and is placed in a part of the same building housing the woodworking factory at Systemvej, under the management of Ove Nielsen. He later recalls that he was virtually bought as part of a load of machines from the Jørgen Bruun engineering works, and that he and his family literally arrived in Billund together with the new machines.

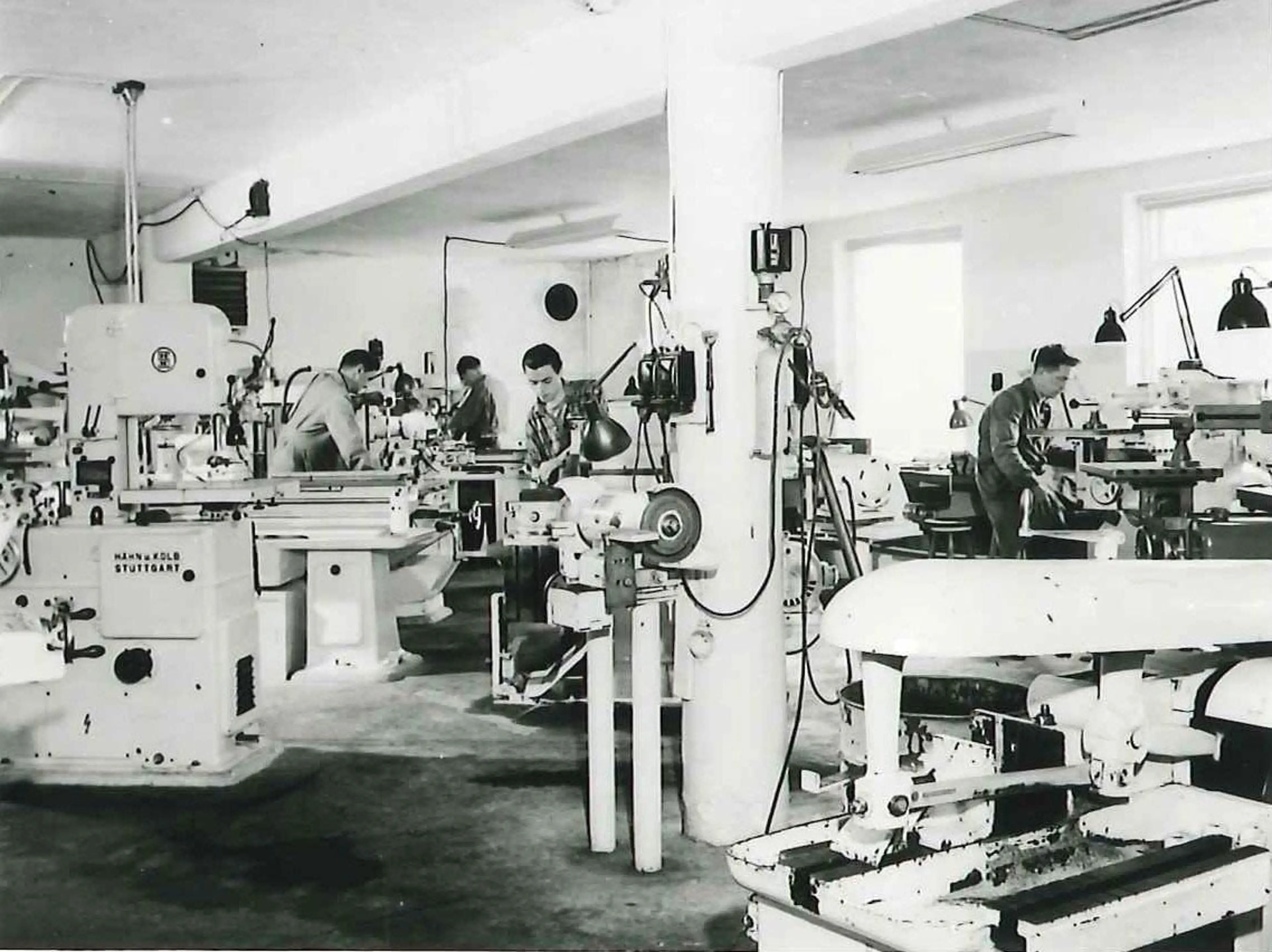

Mold manufacturing, Billund, 1957. On the far right, manager Ove Nielsen

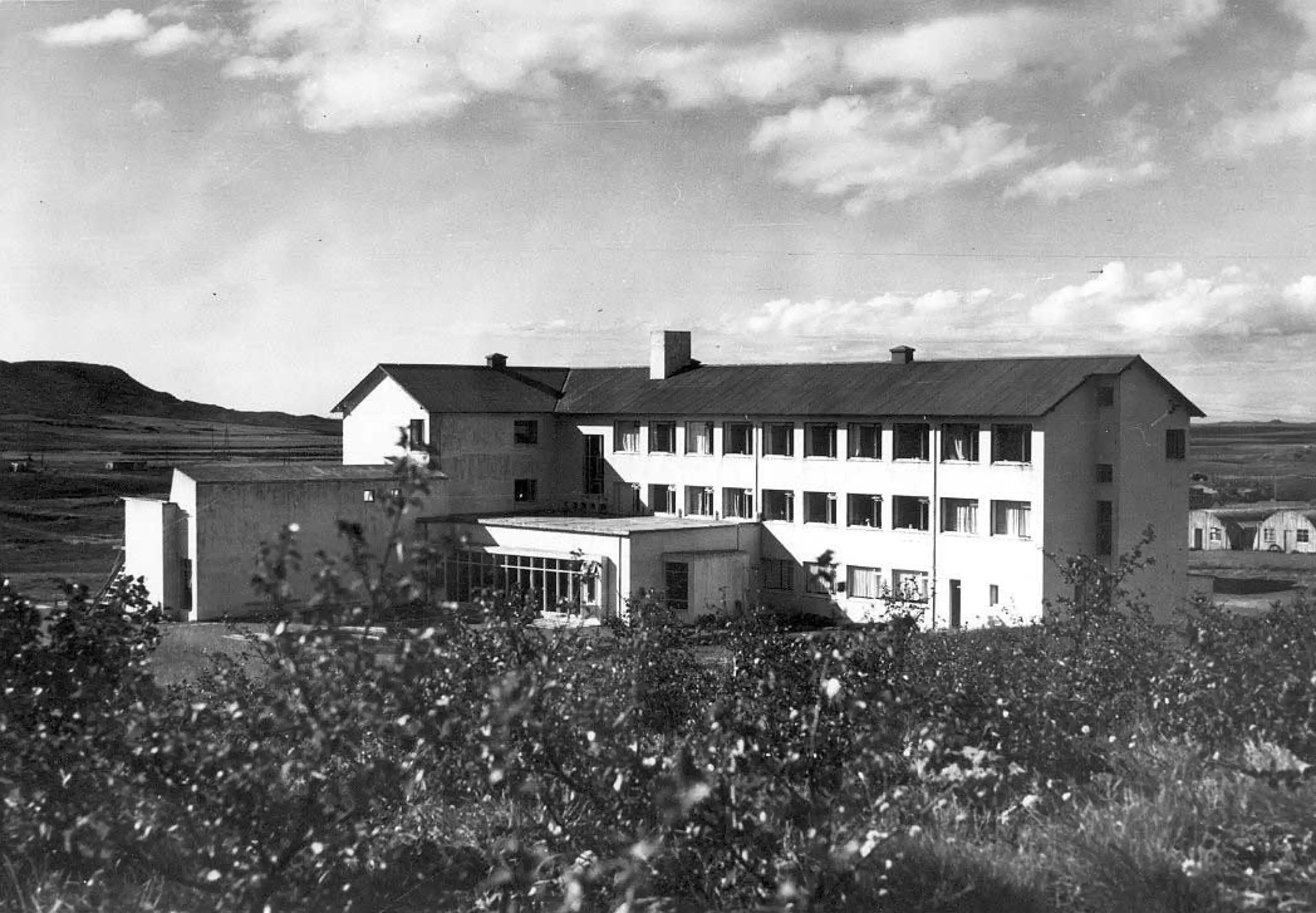

Molding workshops in Billund today

The LEGO Group molding workshops today are located at the Kløvermarken and Kornmarken facilities in Billund. The workshops are now divided into several departments specialized in designing, testing and manufacturing of prototype molds.

Mold Qualification tests the molds that the LEGO Group buys from its four external suppliers, which have supplied molds since 2005. It also adjusts molds or repairs worn molds, which are still suitable for use. All molds must be passed by Mold Qualification – only then are they good enough for the production of LEGO elements.

At Mold Maintenance the molds that have been in production are taken apart and cleaned before being placed back in the molding machine. On average it takes about two weeks from the department receives the mold that needs maintaining until it is ready for production again. The production time of a mold between cleaning is four weeks. The Mold Maintenance department has 18.000 repairs per year.

Prototype and Mold Manufacturing is the workshop that makes prototype molds and designs molds for new LEGO elements.

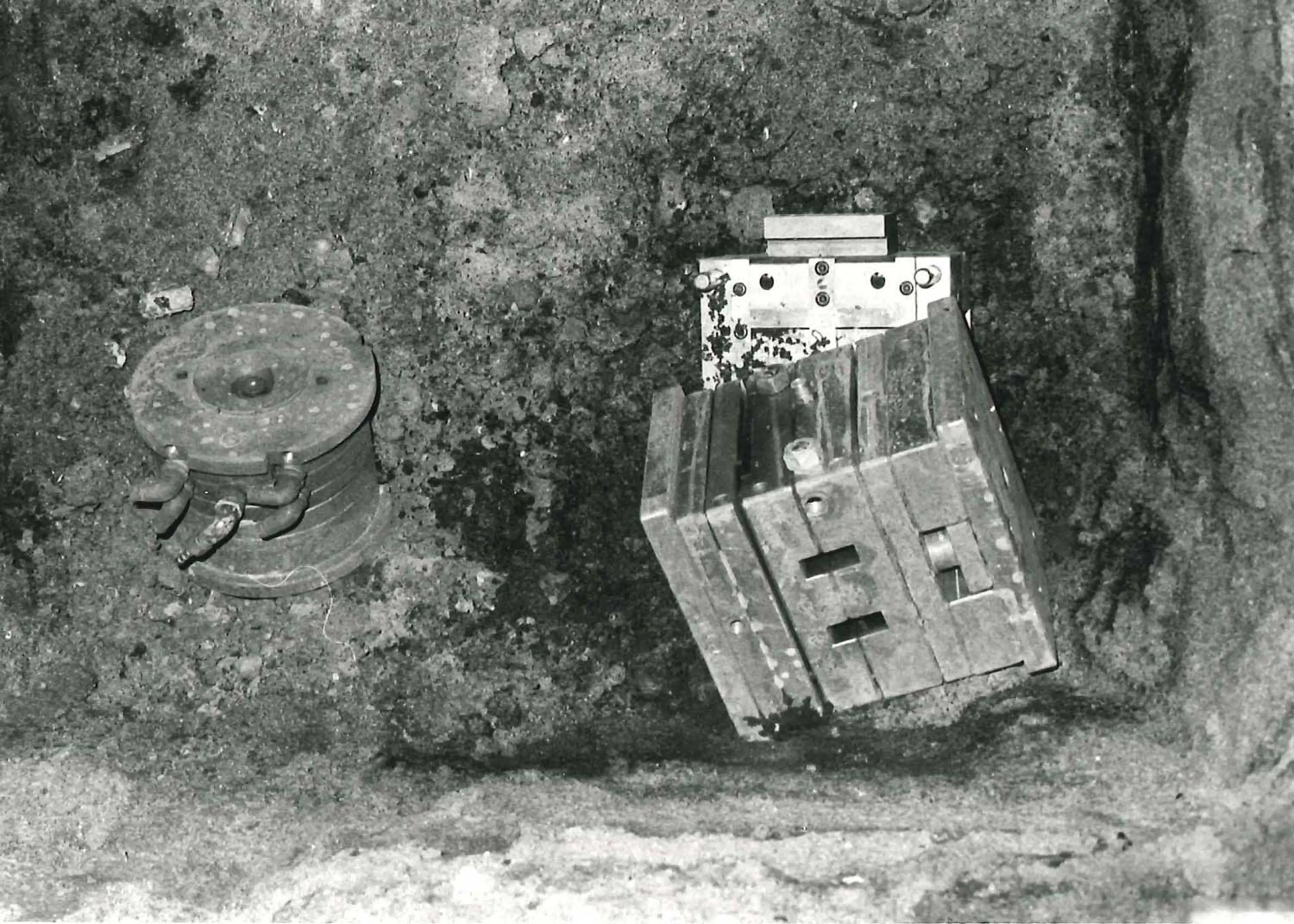

Mould Maintenance at Kornmarken, Billund, 2014