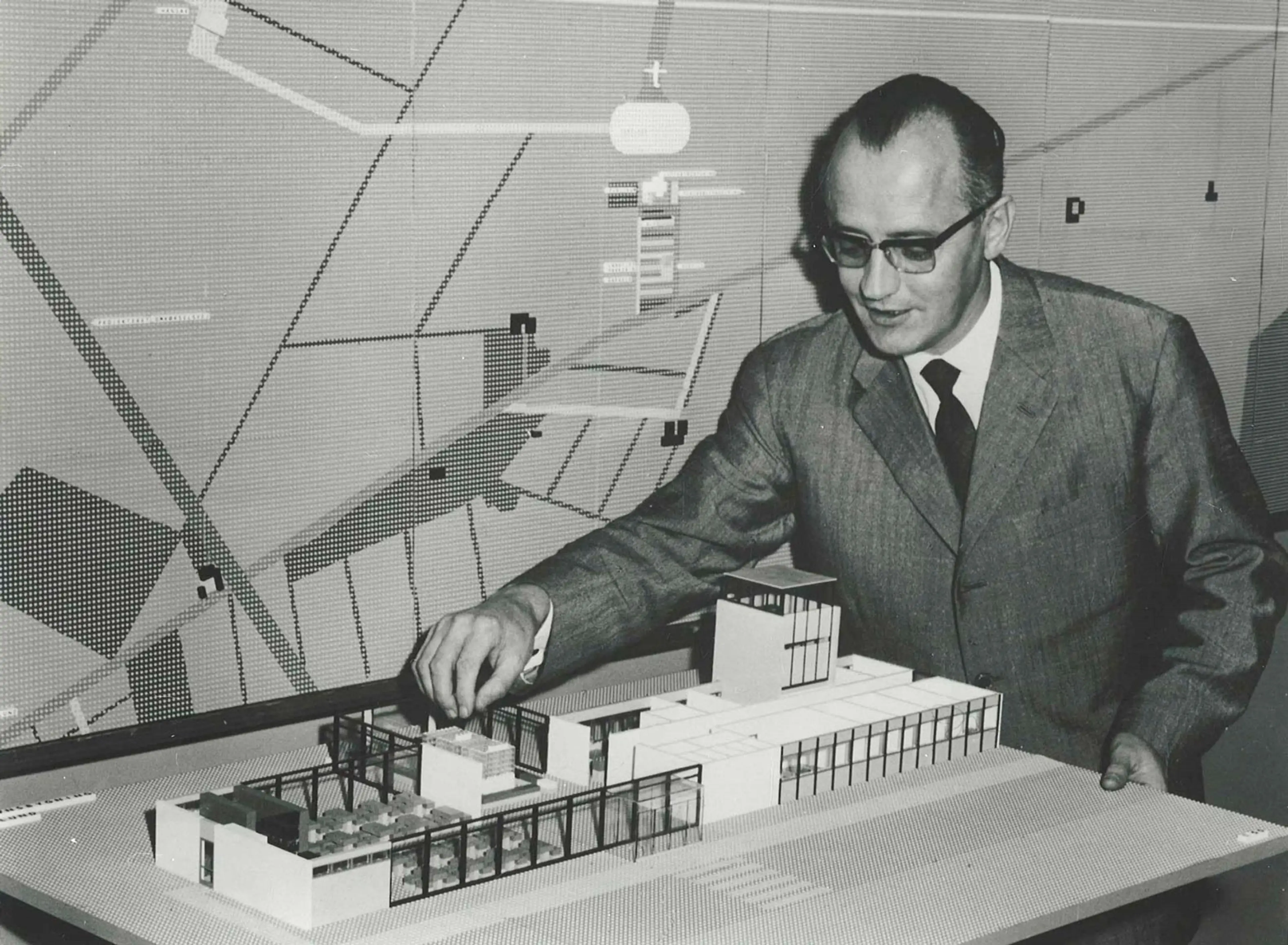

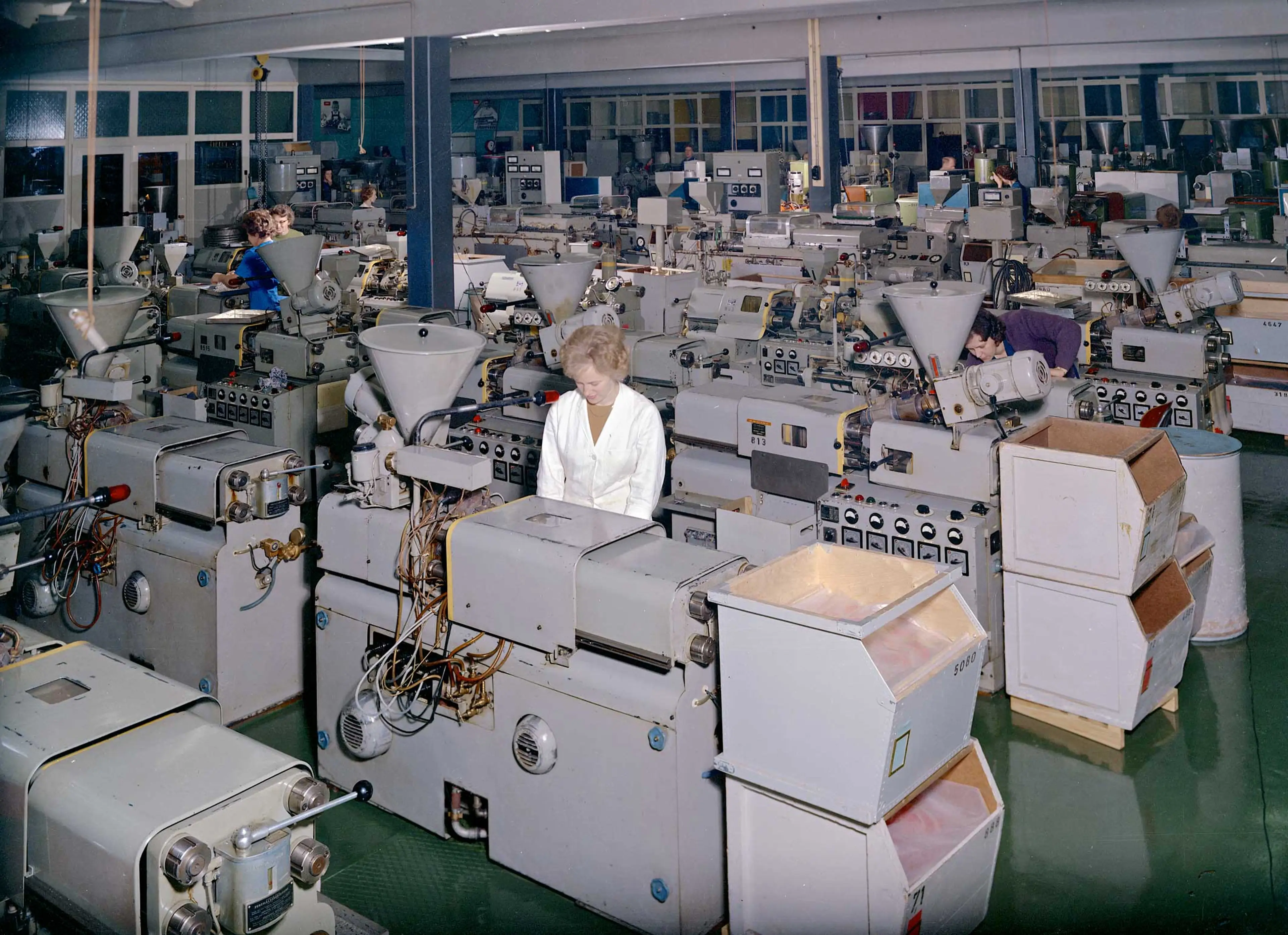

In 1961, the LEGO Group hires Hans Schiess to oversee plastic molding in the factory in Billund. Bringing with him profound knowledge of molding and molding processes this hiring is soon to revolutionize the company´s molding processes.

A pioneer

Hans Schiess is a pioneer in the world of plastic molding and becomes the driver behind the LEGO® molding philosophy, which describes principles for close control of the molding process, the so‑called PE method. The first systematic training courses in molding technique for supervisors are held in 1963.

Hans Schiess, 1963

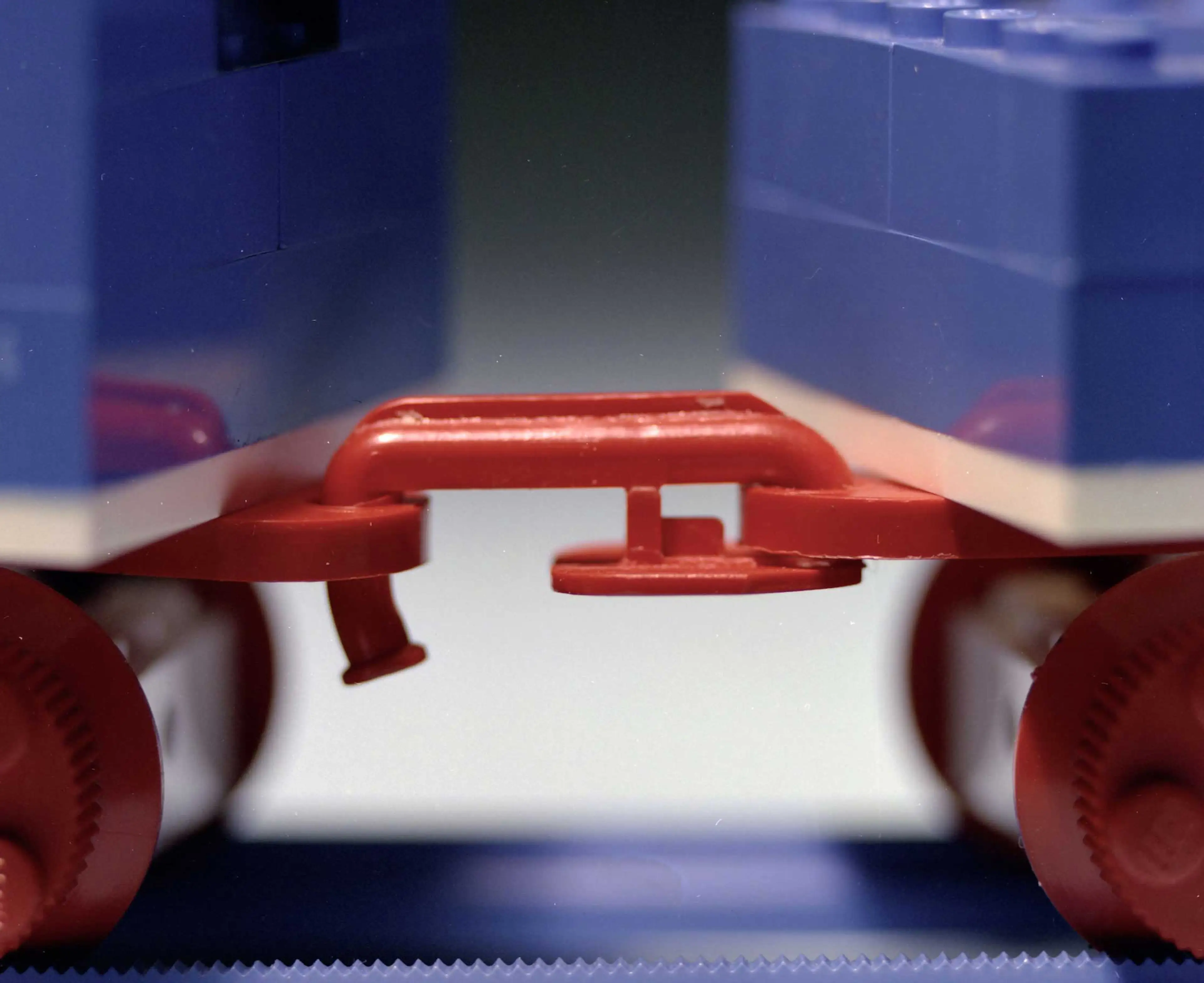

From all the experiments and calculations that Hans Schiess makes, comes a wealth of knowledge on injection molding and the quality of molded items. At the same time, the molded pieces can be optimized, remaining within the range of desired quality, but also with a shorter molding cycle. All this combines to develop and improve the company’s molding machines.

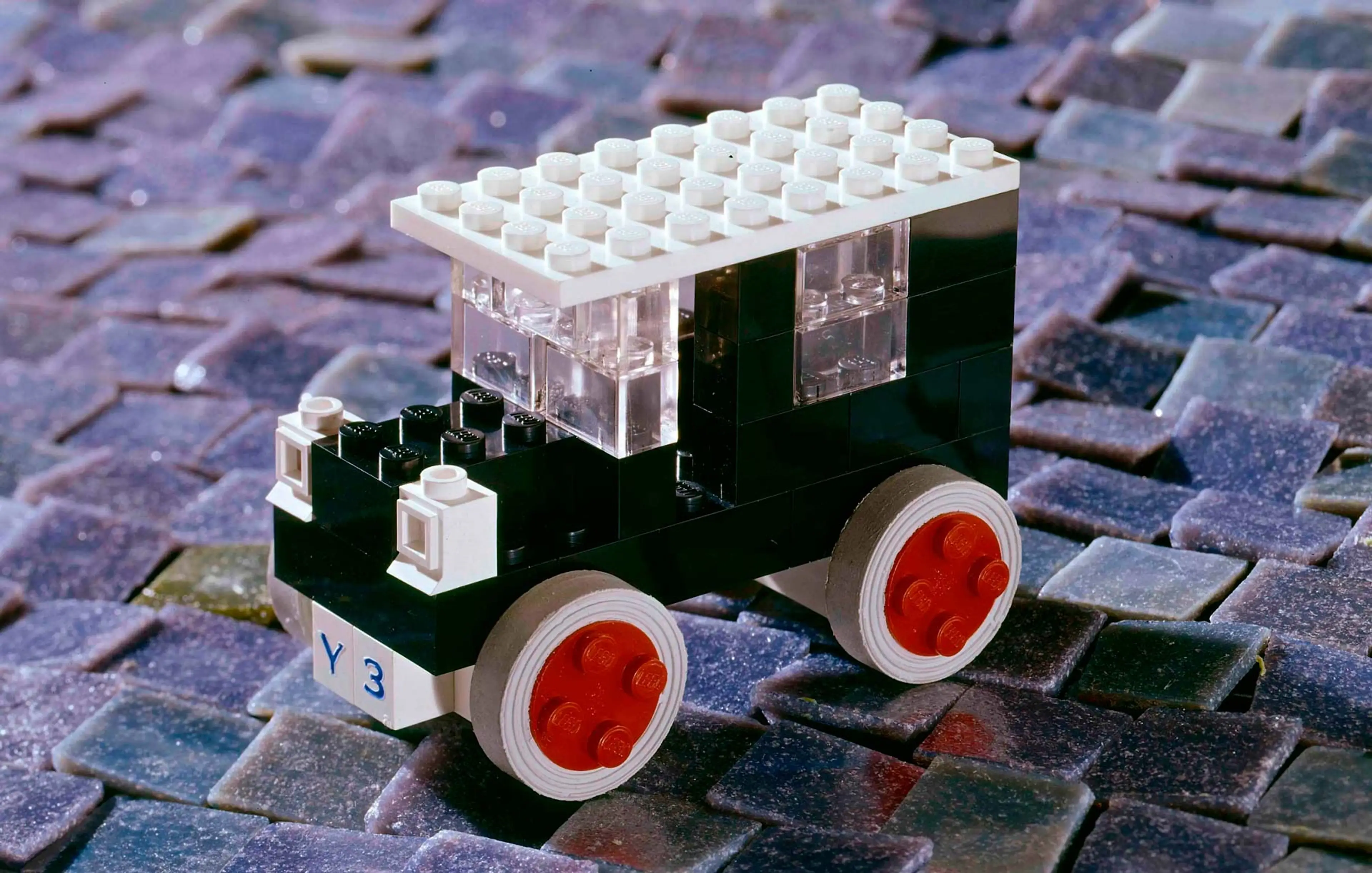

From Cellulose Acetate to ABS

In 1963, under the supervision of Hans Schiess, the LEGO Group switches from cellulose acetate to the more stable, color‑fast ABS (acrylonitrile‑butadiene‑styrene). This new material permits a greater precision in molding, which can now be done to an accuracy of 1/200 mm. This is a giant leap forward in the LEGO Groups pursuit of creating play materials of the highest possible quality and to this day the majority of LEGO elements are molded in ABS.