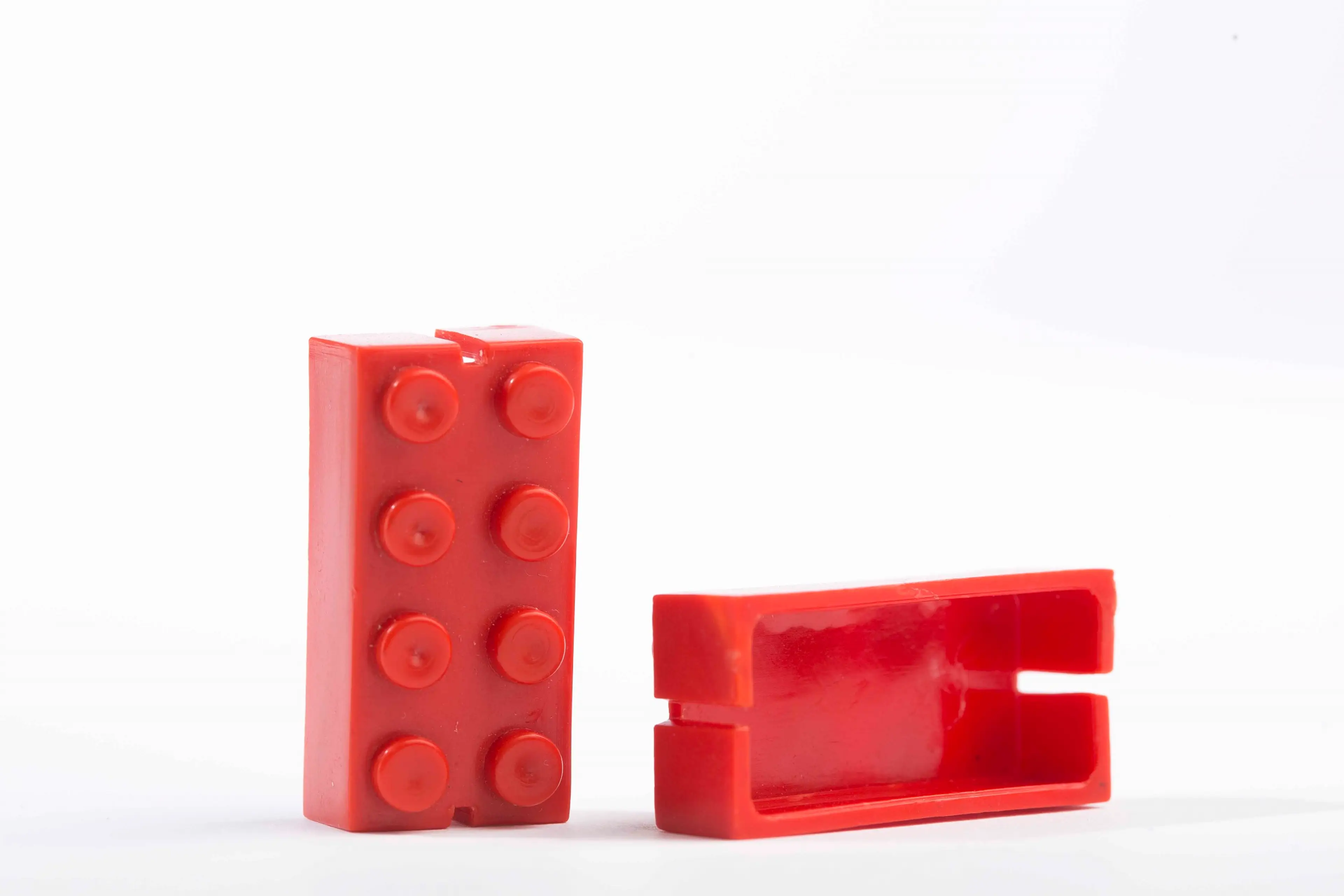

Since the late-1940s, plastic molding of LEGO products has taken place in various factories around Billund. Please join us in a walkthrough of the different sites:

The Systemvej factory

When the very first plastic injection‑molding machine – a Windsor SH – arrives in Billund in 1947, it is placed in a barrack building adjoining the woodworking factory on Systemvej.

As the company buys more and more molding machines, they too are installed in the factory on Systemvej. In 1953, an extension is added to the existing woodworking factory making it the LEGO Group’s first official plastic‑molding factory.

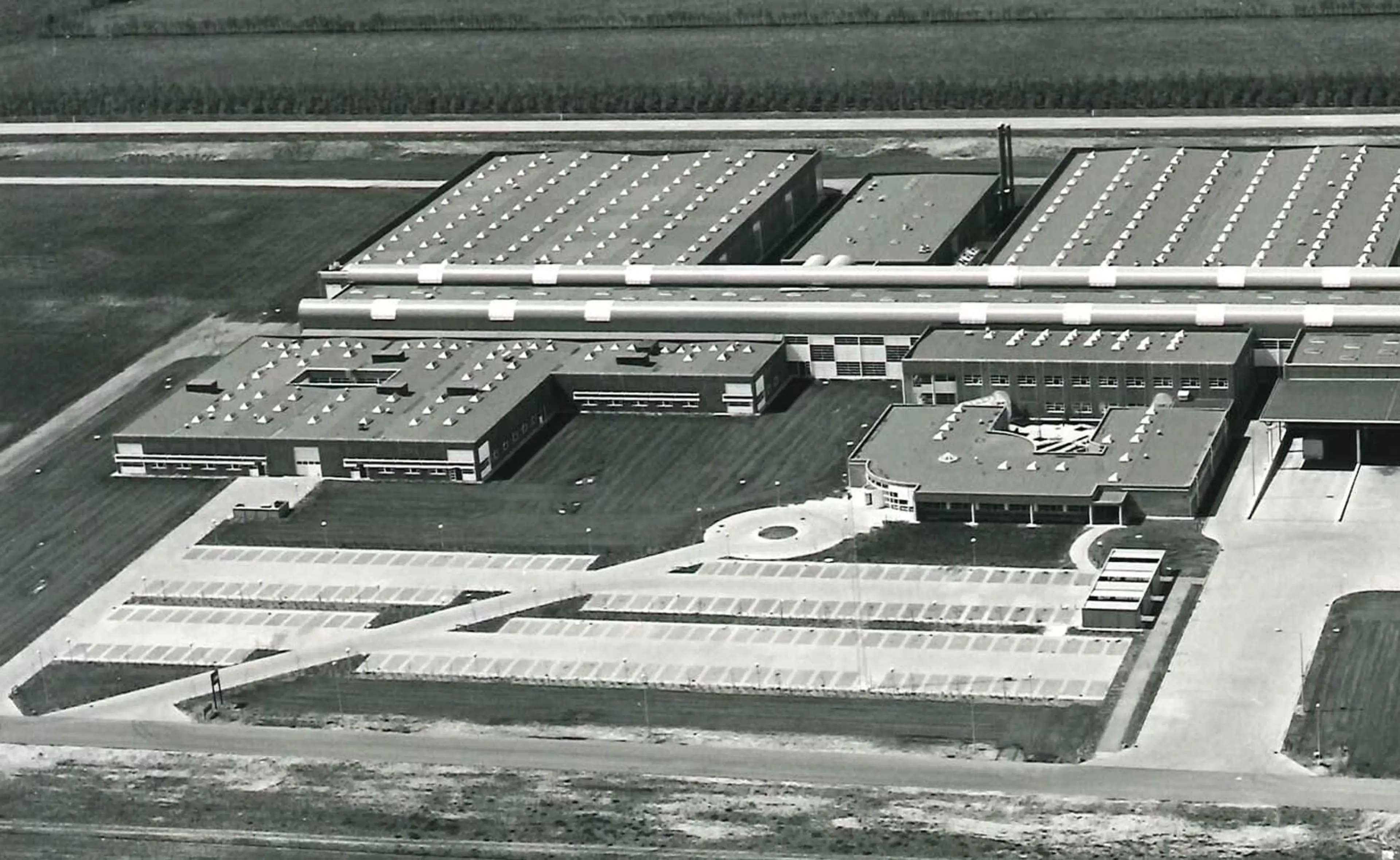

Aerial photo of the Systemvej factory, 1955

By 1953, LEGO owner Ole Kirk Kristiansen has withdrawn from much of the company’s operations and left things in the hands of his son Godtfred Kirk Christiansen. Nevertheless, it is Ole Kirk who gets the idea that the factory should be expanded to create more production capacity. With an eye to the company’s modest profits, Godtfred Kirk suggests that they start with only part of the extension – perhaps a third. To which Ole Kirk explains to his son that he will be the judge of that and that Godtfred should just focus on finding the money. Godtfred Kirk, angered by the rebuff, resigns from the company.

The resignation does not last long and Godtfred Kirk is soon back in the company and the factory in Billund is built according to Ole Kirk Kristiansen’s wishes.

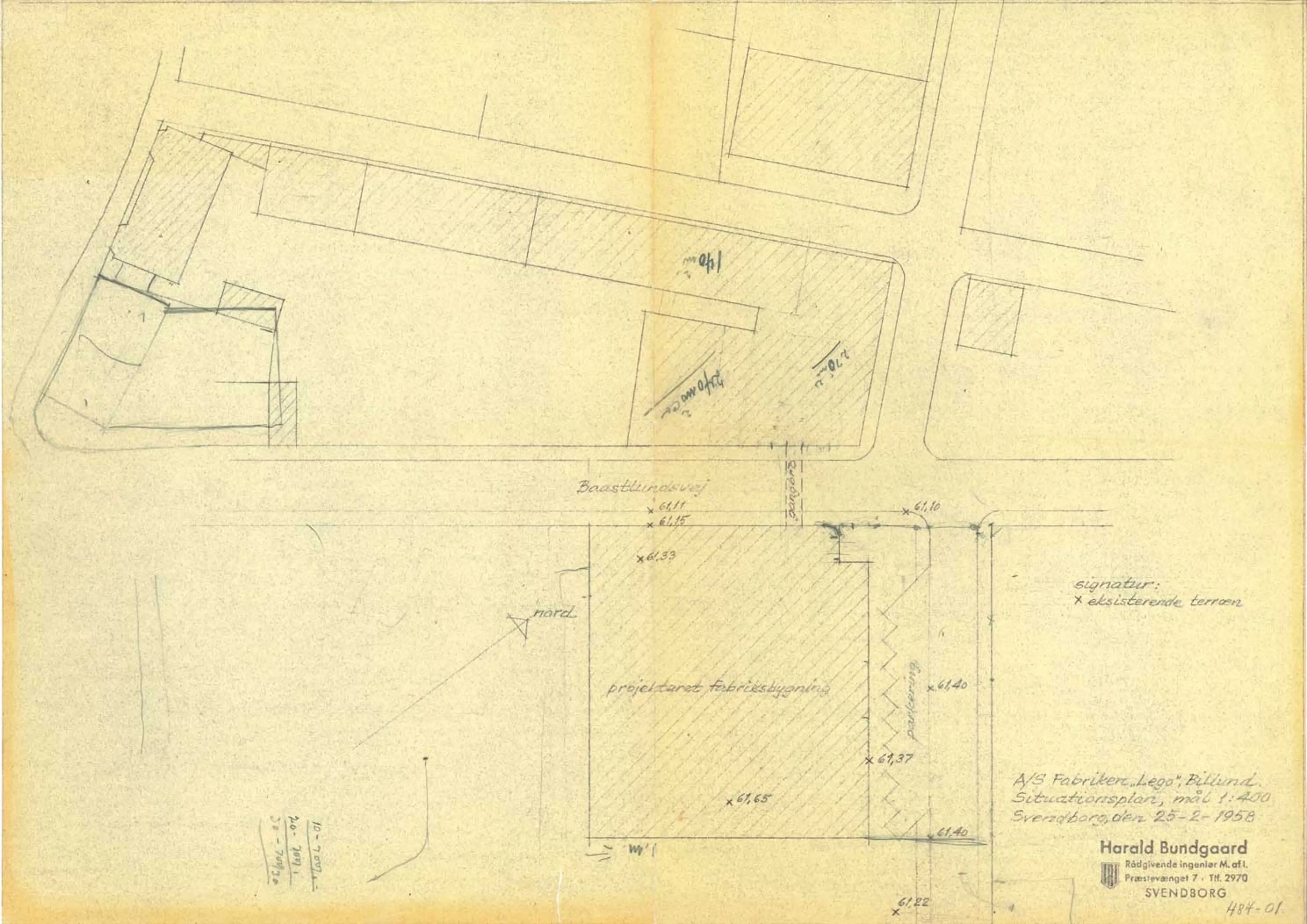

The factory on Systemvej expands again in 1958, with a new molding shop across the road. It now operates 40 injection‑molding machines and 15 more are on order.

Drawing from February 1958 of the planned expansion of the Systemvej factory opposite the existing factory

Construction of the new molding shop on Systemvej, 1958

In 1970 work starts on a new factory with molding shop at Højmarksvej. When it is completed, all production of LEGO bricks is transferred to the new factory and the factories on Systemvej are phased out.

The Højmarksvej factory

In 1970 a new LEGO factory is built at Højmarksvej, not far from Systemvej. The factory, which takes its name from the local road along which it is built, will incorporate both molding and packing facilities thus centralizing all production in the new factory. The transfer of packing and molding functions from the “old” factories on Systemvej is a gradual process.

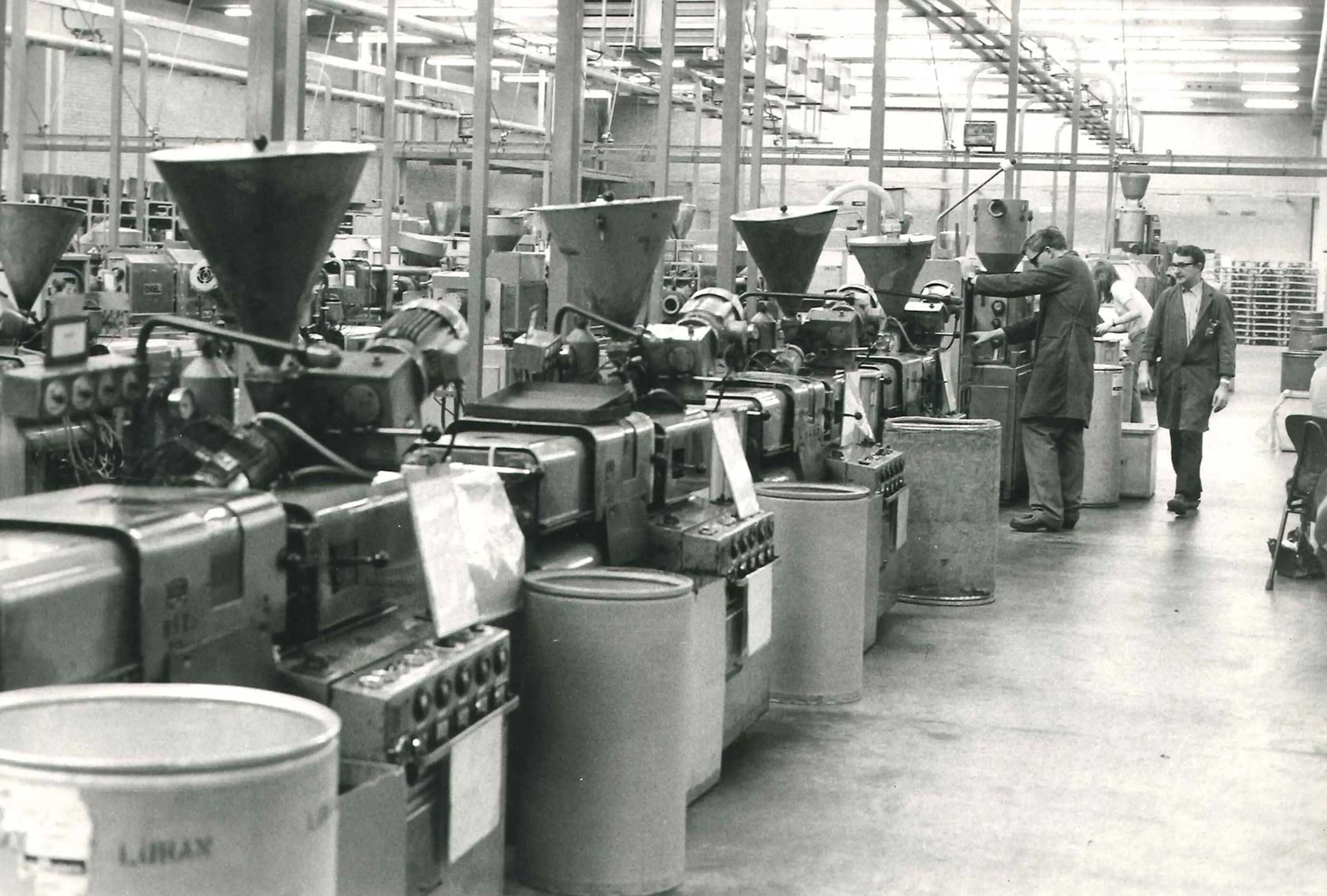

The molding shop is officially opened in 1971, and within a year 721 people are employed in the 18,000‑m² production area. By 1973, 142 molding machines are installed in the factory.

Inside the Højmarksvej factory, 1972

Production expands as business booms in the early 1970s – and by 1974 the factory has to add another 1,600‑m² extension. It is three‑shift, round‑the‑clock working as the plant keeps up with the demand for LEGO bricks.

The molding shop at Højmarksvej transfers in 1987 to a new factory at Kornmarken, which officially opens in 1988. In the years that follow, the Højmarksvej facility lives a chequered existence – during the period 2005‑08 its warehouse serves as an employee shop.

In 2008 the packing facility moves back to Højmarksvej with 350 employees. This is necessary when factory space at another LEGO Group plant in Billund, the Rugmarken factory, is leased to another company.

Højmarksvej functions as a packing facility until 2015, when its packing activities shut down permanently. Packing of LEGO products is then transferred to LEGO Group factories in the Czech Republic, Hungary and, from 2017, China.

The Kløvermarken factory

In 1976 the LEGO Group set up its first factory building at Kløvermarken, an area on the south‑eastern outskirts of Billund. The factory, occupying an area of 6,000 m², is built for the finishing of LEGO DUPLO products.

Business booms and by 1979 it becomes necessary to add a 7,600‑m² extension to the factory.

In 1981 another new factory called Kløvermarken West is added. It is officially opened on November 9, 1981, with 30 molding machines operated by 18 people working in three shifts.

In the mid-1980s production at Kløvermarken is reorganized to make it a ”test molding shop” prior to construction of the Kornmarken factory. “Test molding shop” included the testing of connections to the machines and working distance between them.

Aerial photo of the Kløvermarken factory, 2013

As the LEGO Group builds new factories, the Kløvermarken factory is gradually phased out and given the status of “peak‑load molding plant”. It shuts and reopens several times to meet the need for extra molding capacity. Most recently, the Kløvermarken facility reopens in October 2012.

In early August 2013 the LEGO Group announces that the Kløvermarken factory once again will close. This time, however, it is not expected to reopen. Instead, the new factory extensions at Monterrey and Nyíregyháza and the new plant in China, are expected to be able to handle future demand.

The Kornmarken factory

In the mid-1980s, the LEGO Group builds a new factory at Kornmarken, an area adjacent to Kløvermarken. The factory machines are started up in June 1987, and the 20,000‑m² complex officially opens in 1988.

The principle behind the factory is to construct a series of flexible, modular buildings which function as independent work areas. When it opens, the factory has four modules but by 1992 it has added another eight. Gradually, the factory fills up its 12 modules with a total of 760 molding machines.

.jpg?width=3840&quality=68&auto=webp&format=webply)

Inside the factory, 1988

Aerial view of the Kornmarken factory, 2013

In 1992 the factory adds a 13.5‑m high, fully automatic high‑bay warehouse for storing LEGO elements molded in the Kornmarken factory before they are processed or packed at one of the LEGO Group’s other plants. The warehouse has a capacity of 162,000 boxes.

After the factory at Kornmarken has expanded to a total of 12 modules in 1992, there is no more room to expand. As there is still a need for more molding capacity, the LEGO Group begins the construction of a new factory immediately adjacent to Kornmarken in 1993. The factory will be known as Rugmarken.

The Rugmarken factory

In 1993, the LEGO Group cuts the first turf for another factory in Billund, the Rugmarken facility. The first modules, occupying an area of 18,800 m², come into use in May 1994. Warehouse and transport functions, another 13,800 m², opens in August 1994.

The Rugmarken Factory, 1994

As in the case of the Kornmarken factory, the Rugmarken factory consists of independent modules to which others can be added as the need arises. The plan is for Rugmarken eventually to consist of 10 modules – eight for production and one each for assortment packing and warehousing. The factory will also have a finished‑product high‑bay storage facility.

In 2006, the Rugmarken facility is rented out to another Danish company, Sanistål, who will move into the premises in stages, occupying them fully in 2008. That same year packing activities are moved to the former LEGO factory at Højmarksvej along with 350 employees. Today, the only building the LEGO Group has at Rugmarken is an office building.