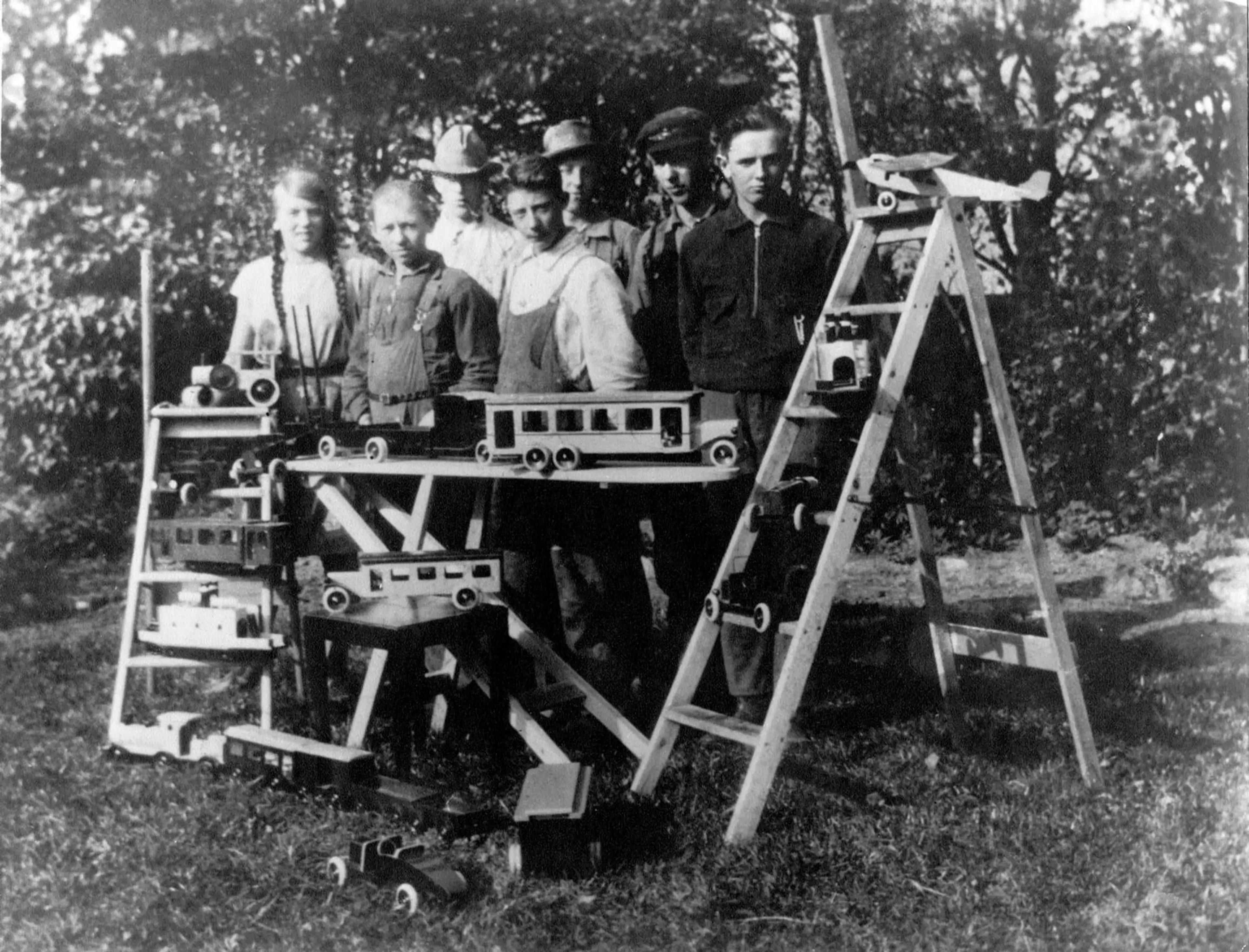

The global economic crisis forces carpenter Ole Kirk Kristiansen to produce new easy saleable products. The beginning of the LEGO Group starts with wooden toys, such as cars, airplanes and yoyo's. Ole Kirk Kristiansen also produces ladders, ironing boards, Christmas tree stands and other articles for everyday use. It is a tough beginning for the company and Ole reaches out to his family for help. The family does not always agree with Ole Kirk Kristiansen. When he asks his brothers and sisters to act as guarantors for a loan of DKK 3,000 to secure the company’s future, one of them asks: “Can’t you find something more useful to do?” Ole Kirk Kristiansen repays the loan at compound interest in 1939. It is a big day in his life, his son Godtfred Kirk Christiansen later recalls.

The first product line is presented in 1932

LEg GOdt becomes the LEGO® name

In late 1935, Ole Kirk Kristiansen decides to further concentrate his business on the toy production he started in 1932. This decision involves finding a new name for the company. The company changes its name after Ole Kirk Kristiansen allegedly holds a competition among his employees to find a good name for the business. The competition winner (who can claim the prize of a bottle of Ole Kirk Kristiansen’s home-made wine) is ... Ole Kirk Kristiansen himself, who has played with the two Danish words LEG GODT (meaning Play Well) to produce the LEGO name. The new name is officially used from January 1936. The intention of the name is to reflect quality and children´s right to enjoyable play. Ole Kirk Kristiansen writes later about devoting his life to the manufacture of toys: “It wasn’t until the day I told myself ‘you’ll either have to drop your old craft or put toys out of your head’ that I began to see the long-term consequences. And the decision turned out to be the right one.” Within a few years Ole Kirk Kristiansen has laid the foundations of what is to become one of the world’s leading toy making companies.

Quality above all

Ole Kirk Kristiansen has always guaranteed the quality of his work, something he continues to do in his work with wooden toys. He is convinced that children deserve toys of high quality, made of the finest materials, so that they will last for many years of play. He uses beechwood, which is first air-dried for two years, then kiln-dried for three weeks. It is then cut, sanded, polished and given three coats of varnish or paint. Just like real furniture. Ole Kirk Kristiansen demands quality at every stage of the process, especially from his own children. Son Godtfred Kirk Christiansen once took a consignment of painted wooden ducks to the railway station. Back at the factory, he proudly tells his father he’s done something really clever and saved the company money. “How did you manage that?” asks Ole Kirk Kristiansen. “I gave the ducks just two coats of varnish, not three as we usually do!” Back comes his father’s prompt response: “You’ll immediately fetch those ducks back, give them the last coat of varnish, pack them and return them to the station! AND you’ll do it on your own – even if it takes you all night!”. “That taught me a lesson about quality,” says Godtfred Kirk Christiansen on a later occasion. After the lesson, Godtfred carves out wooden signs of the company motto “Only the best is good enough” and hangs on the wall of the factory to remind employees of the company attitude to quality.

Employees in the woodworking factory with the company motto on the wall, 1954

Purchase of the first milling machine

Ole Kirk Kristiansen is interested in all forms of new technology, which can improve quality and rationalize production. His interest in new technology, tools and machinery, new materials and processing methods is also obvious when it comes to his own company. He has the gift of spotting potential, an ability his immediate family occasionally view with some skepticism. Ole Kirk buys a state of the art milling machine in 1937. He pays DKK 4,000 for it. At the time, a house costs between DKK 4,000 and 5,000. There is no doubt he is making a significant financial investment. The sum he pays for the machine equals one-third of the company’s total profit the previous year. Irrespective of the price of the milling machine, Ole Kirk Kristiansen is in no doubt about the investment; the machine will increase the quality of wooden toys.

Employee at a milling machine, 1938

Children need toys - even in hard times

The outbreak of World War II does nothing to limit Ole Kirk Kristiansen and his toy production. In times of crisis, the demand for toys is greater than ever. During the first two years of the war, the company doubles its sales. Due to the war, all import activity is halted which naturally favors the sale of Danish goods. Later, it is forbidden to use metal and rubber for such things as ... toys. This boosts production of Danish wooden toys and thus also LEGO production.

The fire in 1942

A devastating fire in the factory in 1942 virtually destroys Ole Kirk Kristiansen’s life work. During the night of March 20, 1942, a fire rages through the woodworking factory, but the adjoining family home is saved from the flames. The fire is almost too much to handle for Ole Kirk. He relates the story in his memoirs: “At three o’clock in the morning one of the young men who sleep in the workshop comes and shouts ‘The factory’s burning!’ It was a shocking message – and painful. I struggled to get a grasp of the situation but I had to pause for a moment and kneel to God. It was my thanks to him who knows all things, and it gave me peace and quiet in my mind.” Ole Kirk almost abandons the idea of rebuilding the factory. The insurance cannot cover the loss and construction of a new production facility. He receives a number of offers from other parts of Denmark to build a factory but finally decides to remain in Billund, thereby securing the jobs of his 26 employees. It becomes possible to rebuild the factory with the accommodating attitude of Vejle Bank, which grants Ole Kirk the necessary loan. With the assistance and support of family and employees, the first dedicated toy factory is built at the site of the old woodworking factory. By the end of the year production has resumed, and by the following year the company is employing 40 people.

LEGO employees assessing the damage to the woodworking factory after the fire in 1942